Bringing Precision to the Production Line: The MAS-i2 Selective Soldering Machine at productronica 2023

- 2023-11-20

- Company News

- Posted by: admin

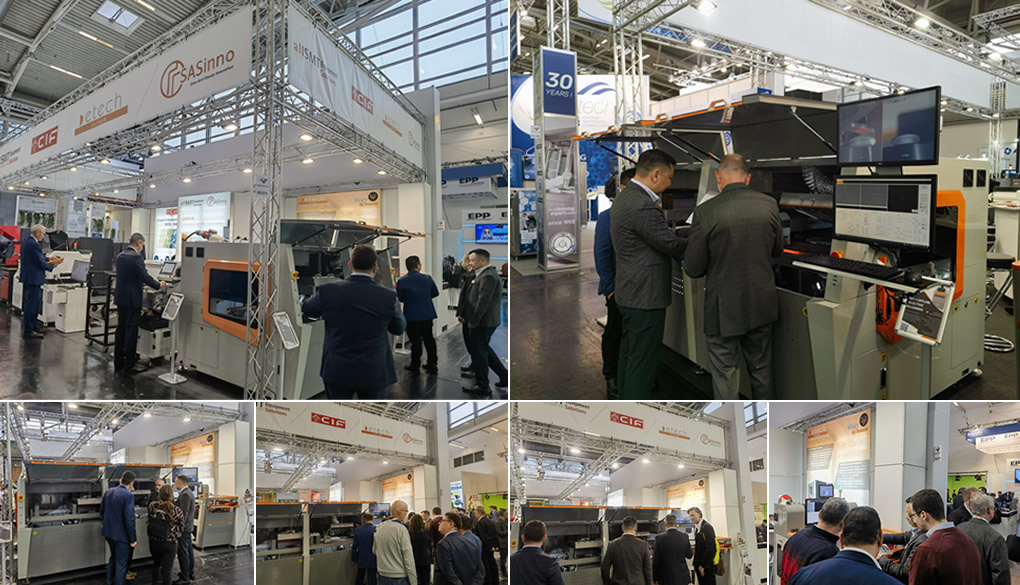

The tech world is buzzing with the latest advancements in manufacturing technology showcased at productronica 2023. The event showcased the MAS-i2 Selective Soldering Machine, a revolutionary system that stands out as a pinnacle of PCB manufacturing innovation. This machine has not only captured the attention of electronics engineers and technology enthusiasts but has also set a new standard for inline soldering automation.

Navigating the Maze of Electronics Manufacturing Trends

Navigating the rapidly evolving maze of electronics manufacturing trends can be complex. As technologies advance and consumer demands shift, the landscape of electronics manufacturing continuously transforms. One of the most critical components of this evolution is the soldering process, which directly impacts the quality and durability of electronic devices.

The MAS-i2 Selective Soldering Machine presented at productronica 2023 integrates cutting-edge technology with intuitive design, addressing the need for high-precision and high-reliability soldering solutions. This post will explore how the MAS-i2 is contributing to the efficiency and excellence of printed circuit board (PCB) assembly across various industries.

Understanding Selective Soldering: A More Strategic Approach

Selective soldering is a strategic departure from traditional wave soldering methods. By targeting specific areas of a PCB with precision, selective soldering minimizes the risk of heat damage to sensitive components and reduces the need for post-solder cleaning. This process is particularly beneficial for high-mix, low-to-medium volume PCB manufacturers where adaptability and efficiency are paramount.

The MAS-i2 system uses an Electro Magnetic Pump (EMP) to deliver solder accurately, without turbulence or the need for nitrogen. This pioneering technology ensures precise control over the soldering process, optimizing throughput and performance. For manufacturers, the high return on investment is evident through increased production yields and reduced material waste.

Introducing the MAS-i2: Features Redefining Soldering Excellence

At its core, the MAS-i2 represents a fusion of innovation and industrial craftsmanship. It integrates advanced motion control algorithms with high-resolution optics for component detection and positioning. The machine's closed-loop flux and precise pre-heating mechanism ensure clean, uniform solder joints every time.

The system's user-friendly interface allows operators to easily program and monitor the soldering process. With features such as recipe management and on-the-fly adjustments, the MAS-i2 empowers manufacturers to be agile and responsive to changing production demands.

The Power of Adaptive Soldering Technology

The MAS-i2 system is equipped with Adaptive Soldering Technology, a dynamic control system that automatically adjusts parameters to optimize solder quality. Through real-time feedback and analysis, this technology continuously refines the soldering process, compensating for variations in board design and environmental conditions.

The adaptive nature of this technology not only improves the first-pass yield but also reduces the need for skilled operators, making the MAS-i2 an accessible and efficient solution for manufacturers worldwide.

Sustainability in Soldering: The MAS-i2's Environmentally Friendly Edge

Sustainability is a growing concern in the electronics industry, and the MAS-i2 reflects a commitment to environmental responsibility. Its lead-free solder compatibility and recyclable flux management system minimize the ecological footprint of the soldering process.

By utilizing the EMP's electromagnetic forces, the MAS-i2 eliminates the need for compressed air, lowering energy consumption and carbon emissions. The machine's modular design also contributes to sustainability, allowing for easy maintenance and reduced downtime.

In Action: How the MAS-i2 Elevates PCB Manufacturing

Productronica 2023 showcased the MAS-i2's impact on PCB manufacturing across diverse applications. From automotive electronics to medical devices, the machine's versatility accommodates a wide range of product complexities. The precision and repeatability of the MAS-i2's soldering process ensure a level of quality that meets the stringent standards of safety and reliability in these critical sectors.

The exhibition also highlighted the MAS-i2's role in nurturing innovation. By automating the selective soldering process, engineers and PCB designers are free to explore new design paradigms without compromising manufacturability.

The Future of Electronics Manufacturing: MAS-i2 Leading the Way

As electronics continue to shrink in size and grow in complexity, the importance of precision soldering cannot be overstated. The MAS-i2 Selective Soldering Machine, with its state-of-the-art features and sustainable practices, is a harbinger of the future of electronics manufacturing.

With a focus on quality, efficiency, and adaptability, the MAS-i2 paves the way for a new era in PCB assembly. It embodies the spirit of innovation and the relentless pursuit of excellence, qualities that will undoubtedly define the next generation of electronic devices.

For manufacturers looking to stay ahead in the fast-paced world of electronics, embracing the MAS-i2 is not just an investment in technology; it's a step towards securing a competitive edge and shaping the industry's future.

In conclusion, as we dissect the brilliance of the MAS-i2 Selective Soldering Machine unveiled at productronica 2023, it's clear that it isn't just a piece of equipment—it's a vision of what's possible and a tangible demonstration of progress in electronics manufacturing.

The MAS-i2 Selective Soldering Machine has redefined precision and reliability in PCB assembly. Its showcasing at productronica 2023 not only presented a superior solution for electronics manufacturing but also signaled a transformative milestone in the industry. As we move forward, it will be fascinating to observe how this technology continues to shape the electronics landscape, nurturing a culture of innovation and quality.

Prev

Next